50 years of experience in industrial mechanics

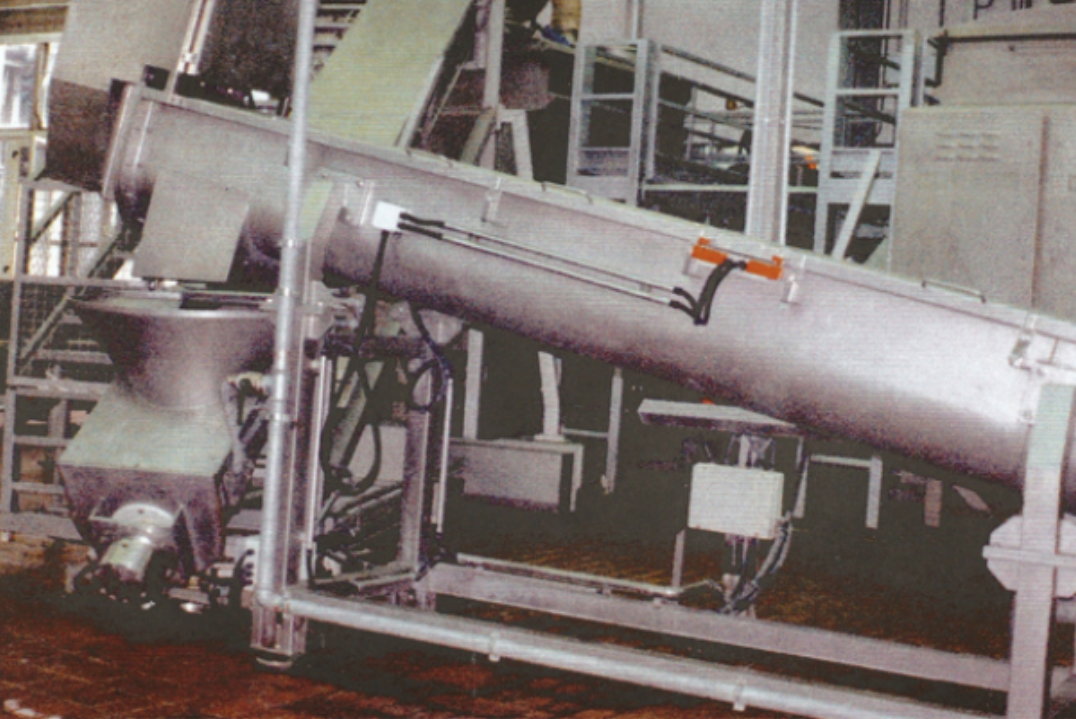

With over 50 years’ experience in the industrial mechanics sector, FERRARONI AFP designs and manufactures customised machines and plants for small and medium-size food companies. These mainly include elevators and tippers for all types of products and containers, centrifuges for processing slaughterhouse by-products, machines for sausage and salami factories, and slaughterhouse equipment. In recent years the company has successfully taken part in international fairs such as IFFA in Frankfurt and Cibus Tec in Parma. Increased demand has led to expansion of its manufacturing facilities and the use of more advanced design software.

WHY CHOOSE Ferraroni AFP? Ferraroni AFP designs and manufactures, in its own facilities, the most suitable machines and solutions for its customers’ production processes. In recent years, our personnel’s professionalism and skill have allowed us to supply complex sectors with effective, innovative solutions that are tailored to customer requirements. Our skilled maintenance staff provide prompt service and have access to a well-stocked spare parts warehouse and a full complement of tools and equipment.

Company time line

-

1965 - Establishment

Founded in 1965 as Officina Meccanica A. Ferraroni, the firm specialises in the construction of machines and equipment for sausage/salami factories and slaughterhouses. -

1980 - Officina Meccanica A. Ferraroni & C snc

In the 1980s, with the arrival of Fari Emilio, the company becomes Officina Meccanica A. Ferraroni & C snc, expanding its product range and specialising in the construction of elevators and tippers. -

2008 - Ferraroni AFP SRL

In 2008 Andrea Ferraroni leaves the company. The firm becomes Ferraroni AFP SRL following the entry of two new partners (including Luca Papini) who have already worked extensively with the company. They begin working alongside Emilio Farri. -

2020 - Leadership

Today, Ferraroni AFP Officina Meccanica leads the way in the design and manufacture of chain and hydraulic elevators-tippers for all types of products and containers and in the manufacture of slaughterhouse by-product processing centrifuges. The range includes conveyor belts, screw feeders, tumblers for cooked meats, pork product skinning units and small-scale pig and cattle slaughter lines.

English

English